How

to make a groovy jointer

No, not a tool for aging hippies with arthritis... A simple modification to an ordinary woodworkers jointer that puts grooves in boards. Lots of grooves. Lots of grooves fast! Lots of toenail gripping grooves! ...Toenail?

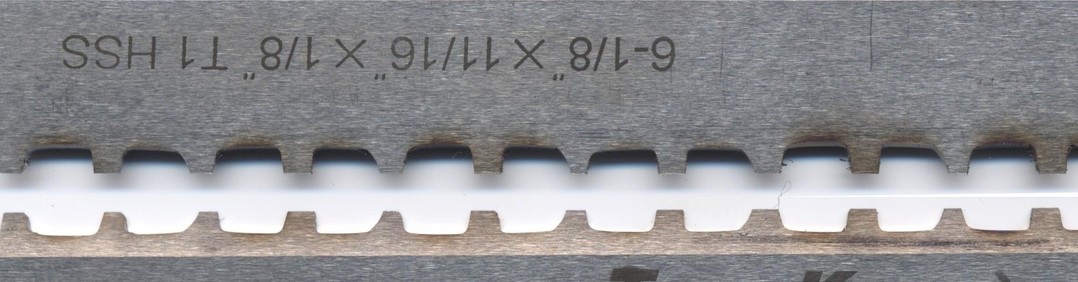

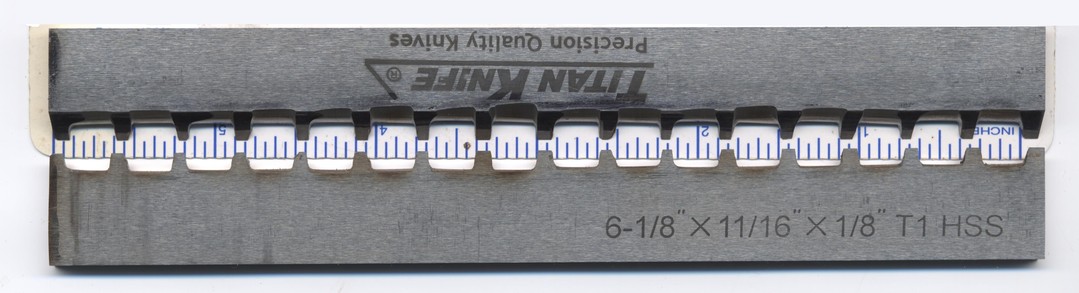

Now that we have seen what it can do lets see how to bork up a brand new set of jointer knives.

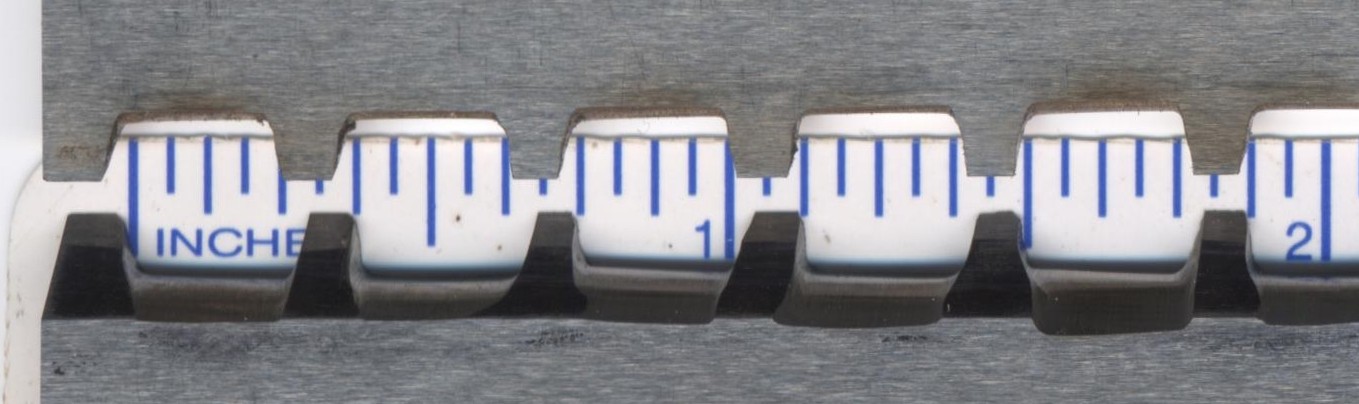

First try on grinding the knives. Since they would not cut deep enough without hitting I went back and ground them slightly deeper and added a radius on the edge that hit first. Also re-dressed the rock on the bench grinder to try for sharper corners in the notches.

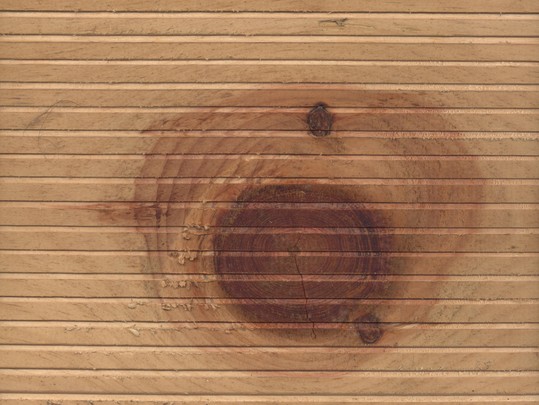

Partially succeeded... Also obvious why all the boards above have exactly 17 grooves.

Zoomed view of same.

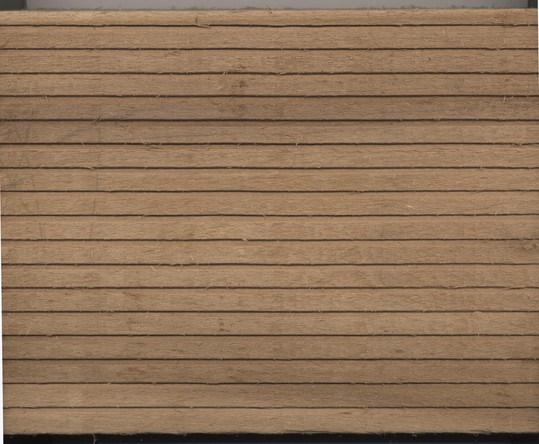

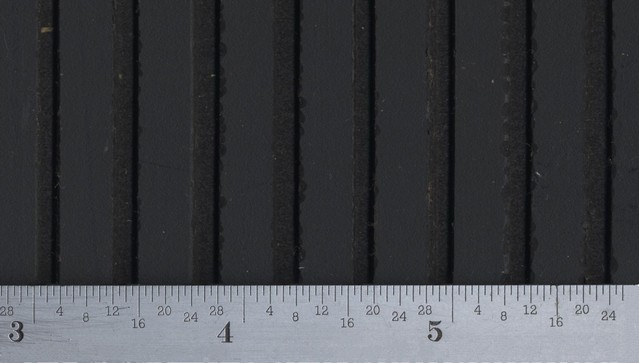

One more test, grooved PVC. Expanded PVC to be specific, the kind that is like a stiff foam in the middle with a hard glossy layer on both sides. A bit pricey, but slightly less so if you have connections with a local supplier. Chipped a bit as you can see, but this was mainly due to my sample being old.

If your wondering just what the heck this loon is doing putting grooves in lumber (and now plastic) that looked perfectly fine with out the grooves? Bat Houses! The baffles inside need grooves when your not using rough sawn lumber.

Currently have five active bat houses on the back of our house and our colony of bats has grown from 7 in 2010 to over 200 the last time I counted them in 2017.

A few years back had hopes and dreams of starting a business selling bat houses. Those plans are on indefinite hold...

William Bagwell